Torsion Springs: Essential Mechanism Components

Machines pertain to any form of network or contraption that simplifies work or reduces exertion of human effort. And while all of us use devices daily, we’re generally not aware of their components. In this article, we’ll discuss a standard part of numerous household mechanisms and heavy-duty products: torsion springs. Moreover, we’ll tackle their applications, configurations, and factors to consider for selection.

What Are Torsion Springs?

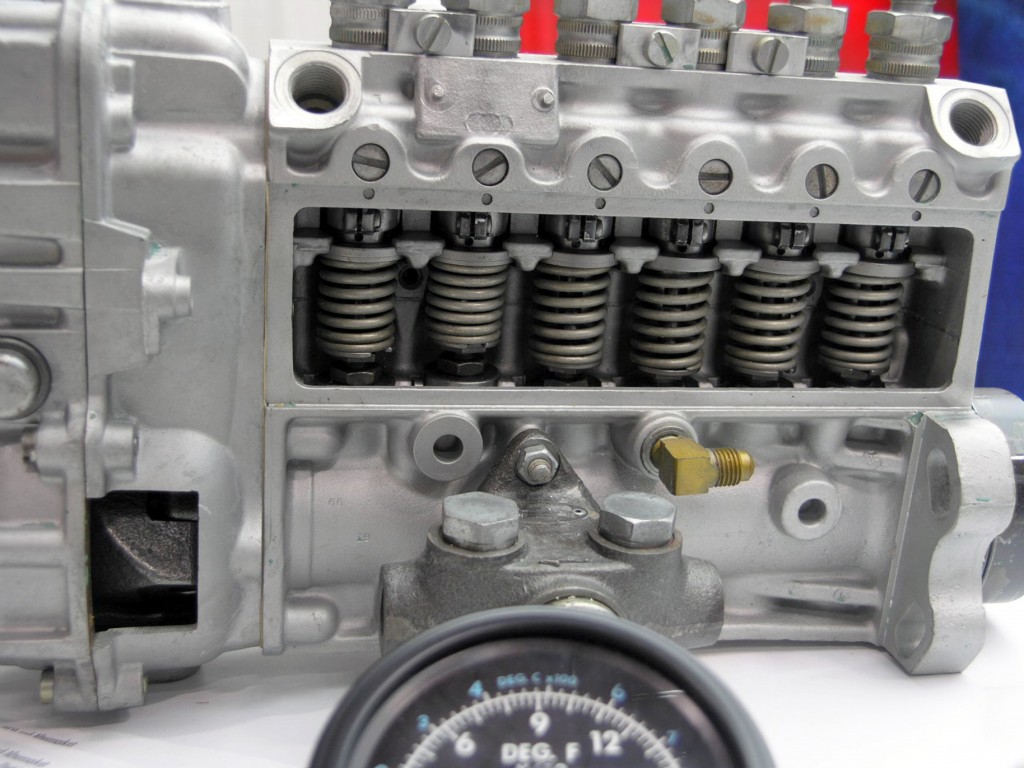

Torsion springs are helical springs tasked with exerting rotary force or torque on other components to which their ends are attached. Thus, when these parts are rotating around the spring, it pushes them back towards their initial position. Also, although they are called “torsion” springs, they aren’t subjected to torsional pressure but on bending stress. Furthermore, they can handle the storing and releasing of angular energy to hold mechanisms in place in a static manner. To put it more simply, they provide components with stability and resistance to twist force.

Factors to Consider

When choosing the configuration of torsion springs, it’s essential to take their specific intended use into account. Knowing what they will be used for helps you determine the right size of torsion springs to select. For example, miniature torsion springs are utilized in electronic devices. As for bigger units and applications, larger torsion springs are more suitable. Moreover, considering the application allows you to estimate the load, which is an aspect that you cannot overlook when identifying the required diameter and body length of torsion springs. Lastly, the impacts that arm deflection and friction bring on the torque should also be considered.

Common Uses and Applications

Torsion springs are employed in a lot of applications. For typical household and personal products, examples include clipboards, ratchets, clothespins, and watches. For more heavy-duty applications, torsion springs are used in hinges, ramps, lever returns, hatches and lids, tailgates, and garage doors.

Configurations

- Specifications.Some vital specifications for torsion springs include their performance, dimensions, finishes, and materials used.

The considerations for performance include the spring rate, maximum load, and maximum deflection. As for the dimensions, these pertain to specifications of the torsion springs’ inner diameter, outer diameter, wire diameter, and body length.

For the finishes, common types of coating are black oxide, passivation, zinc, and gold iridite. Lastly, accessible materials used are music wire, hard-drawn steel, stainless steel, and spring steel. However, for light-duty needs, plastic can be sufficient.

- Wind Direction. Torsion springs are designed to work in either a counter-clockwise or clockwise manner. There are also double torsion springs available, which are two torsion springs—with one wounding clockwise and one wounding counter-clockwise.

- Leg. As for the leg configuration, essential specifications include the leg length, leg angle, and leg style.

Torsion springs are widely used in numerous products. If you need them to repair items, such as door hinges in your home, you can ask a hardware store to help you select the right configuration and size. Moreover, many torsion springs suppliers offer torsion springs in Ohio, such as in Columbus, Cleveland, and Cincinnati. Some also provide custom-made ones for more complex contraptions.