10 Ways to Increase Productivity in Pharmaceutical Manufacturing

The pharmaceutical manufacturing industry is one of the biggest drivers of the economy. It’s also highly regulated to ensure that products are safe and pure before they hit pharmacy shelves. The FDA mandates strict quality standards at all stages of production, which can be very stringent and difficult to meet. This can result in a lot of stress for manufacturers who are tasked with the huge responsibility of producing safe and pure pharmaceuticals for patients.

Here are ten ways to increase productivity in pharmaceutical manufacturing:

1. Standardize Workflows

Standardizing workflows is one of the simplest things you can do to increase efficiency in your pharmaceutical manufacturing facility. All too often, people underestimate the power of standardization. Standardizing critical steps in your process will ensure that everyone knows what they are doing and how to do it the same way every single time.

This prevents costly errors that can be time-consuming to troubleshoot and frustrating to implement. You should standardize any critical step in your manufacturing process, including the way you prepare equipment, perform environmental monitoring, handle deviations from specifications, etc.

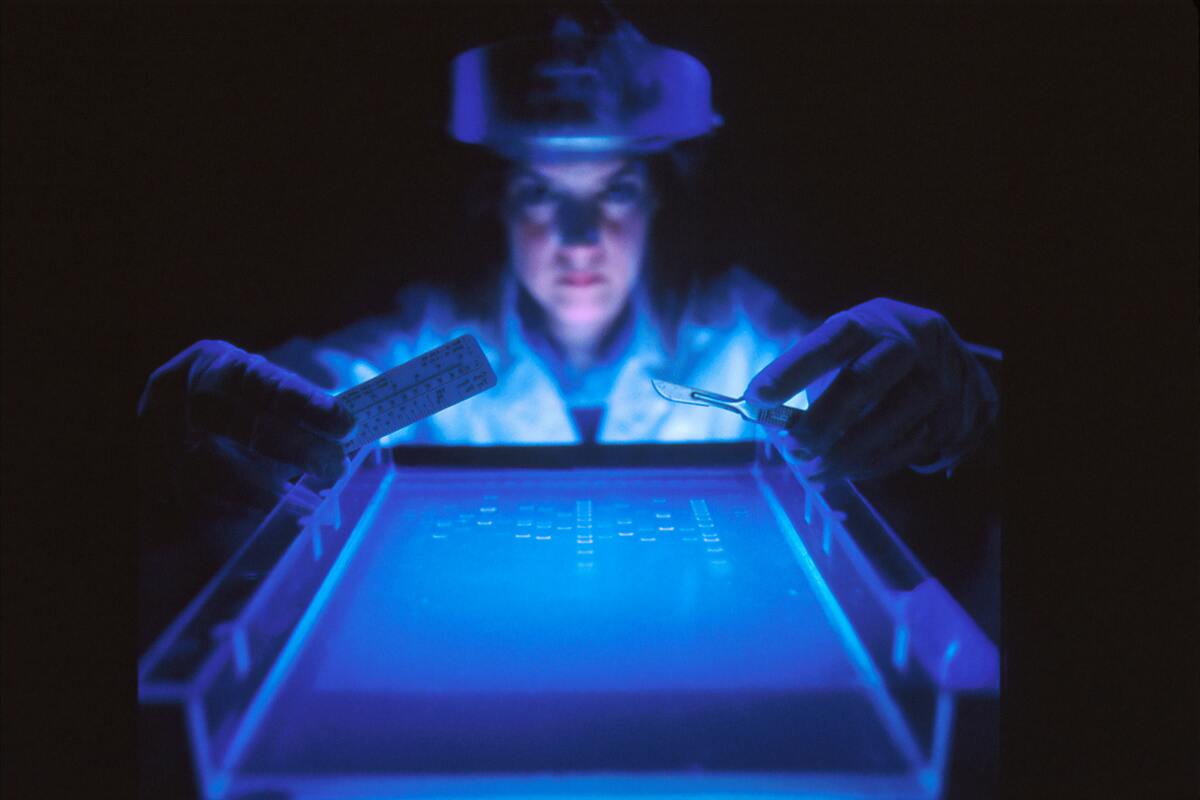

2. Focus on Preventing Contamination

When it comes to pharmaceuticals, preventing Contamination is a no-brainer. The consequences of producing a contaminated product are enormous, so contamination prevention should be at the top of your mind. You can prevent most contaminants by establishing robust preventive controls that include equipment design, proper environmental monitoring procedures, and corrective actions when necessary.

3. Maximize Your Cleaning Efficiency

Cleaning is one of the most time-consuming processes in pharmaceutical manufacturing, which is why maximizing your cleaning efficiency is so important. You want to minimize the amount of time that critical equipment sits idle in-between batches while it’s being cleaned. A good way to do this is by using clean-in-place systems that can clean multiple pieces of equipment at once during downtime between batches.

4. Automate Your Processes

Applied automation is another way to increase your pharmaceutical manufacturing productivity. There are many benefits of using automated equipment, such as:

Fewer errors and more consistent products Increased safety and fewer injuries Improved throughput Less downtime and shorter cleaning cycles

5. Contact Reliable Suppliers

One of the biggest things that can affect your pharmaceutical manufacturing productivity is when you run into issues with faulty parts or equipment. How quickly you resolve this situation greatly depends on how reliable and responsive your trusted air compressor supplier is, for instance, is in helping you get what you need to keep the production line moving.

6. Implement Safe Work Practices

Every day you need to make sure that employees are working in a safe environment. This includes using personal protective equipment (PPE) and proper ergonomics, conducting job hazard analyses (JHA’s), encouraging your employees to be open about any safety concerns they have, and ensuring that your facility is always ready for an evacuation or emergency situation.

7. Track Your Processes

Monitoring your processes effectively is another important factor in pharmaceutical manufacturing productivity. You need to be able to monitor the equipment and procedures you use, as well as how well your employees follow those procedures. You can do this by using advanced software that collects and analyzes relevant data from your process and provides feedback to both management and employees.

8. Make Sure Employees Get the Training They Need to Be Successful

In order to increase productivity, employees must have access to proper training. It’s been said that investments in employee training are actually one of the best ways to improve competitiveness and make a company more successful. Pharmaceutical manufacturers should invest in employee training through education, on-the-job learning programs, and tuition reimbursement.

9. Optimize Your Supply Chain

You can increase your pharmaceutical manufacturing productivity by optimizing the way your company manages its supply chain. Here are a few ways you can optimize your supply chain: Reduce transportation costs and improve delivery times with consolidated shipments Streamline processes to reduce errors, create more efficient delivery schedules, and identify new efficiencies Scale for growth with customized supply chain solutions to support new plants, equipment, or capacity

10. Take Advantage of Technology

The last way that pharmaceutical manufacturers can increase productivity is by taking advantage of technology. There are countless technologies on the market today that can help you optimize your operations and increase both your operational efficiencies and production yields. The most effective method for improving productivity through technology is to implement a system that can monitor, control and regulate everything from your water temperatures to your manufacturing processes.

Pharmaceutical manufacturing is a complex and intricate process that requires a high level of productivity to be successful. By using the seven tips we’ve provided, you can increase your pharmaceutical manufacturing productivity in a number of ways.