Laser Engraving: Best Practice for Stainless Steel

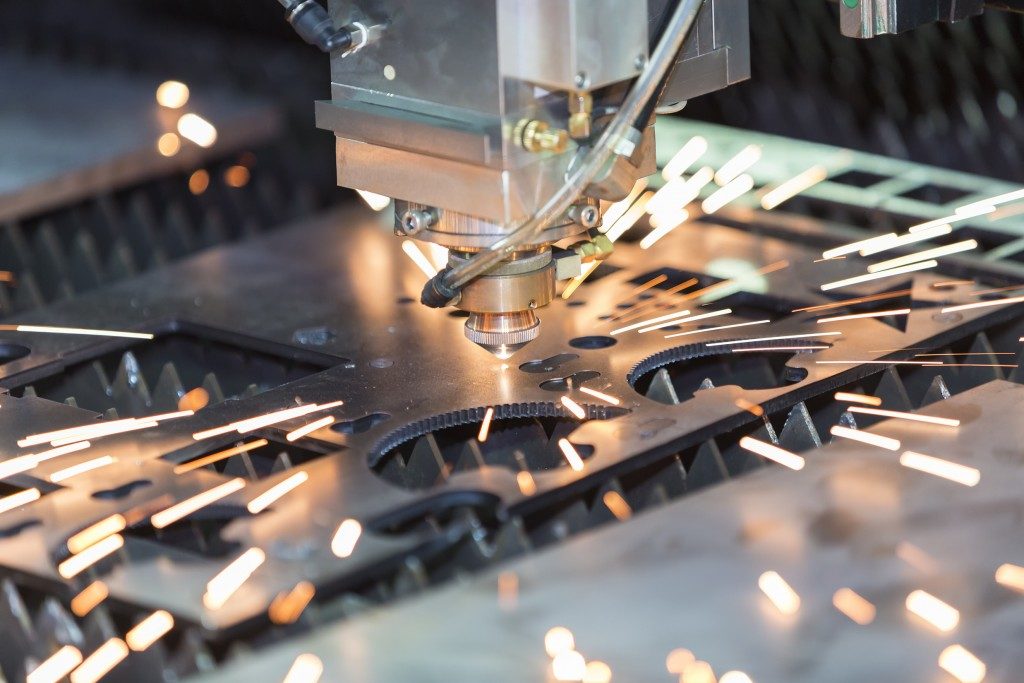

Want to put designs onto stainless steel? One way to do this is thru laser engraving. Laser engraving is a particular type of laser marking on stainless steel that produces a high-powered laser beam to vaporize the surface of the target material. It is best used for materials that experience high wear and tear, as the engraving ensures permanent marking on the surface.

For best results, we listed down some best practices to follow when laser engraving on stainless steel.

Design for laser engraving

Designing for laser engraving is a bit different than the traditional graphics you used to make. When creating designs for this specific project, imagine what the final output will be. You need to consider the steps you need to take to engrave your design accurately to the surface material. Also, you need to use design applications that can produce vector files like Adobe Photoshop, AutoCAD, or Inkscape. Vector files allow you to maintain the clarity and proportions of your design, which is ideal for laser engraving applications.

Increase power, decrease the speed

When laser engraving, you would want to cut more deeply on each pass. This is because deeper cuts tend to withstand wear and tear when the material is exposed to corrosive elements like chemicals. To do this, increase the power of the laser and decrease its speed. Laser engraving machines allow you to configure settings for specific projects.

Engrave with multiple laser passes

When you engrave with a single laser pass, you will notice waste product known accumulating in the razor-thin lines of the engraving. This waste product is known as slag. Slag happens if you try to remove too much material at once, which ruins the contrast in the final product. This is why we don’t recommend engraving with a single laser pass with maximum decreased speed. It’s always best to engrave with multiple laser passes at a reduced speed and moderate power.

Test, configure and calibrate for each project

The process of laser engraving isn’t one size fits all. You have to configure and calibrate your settings in every new project you are making. This is because every laser engraver is different. From the laser type and machine settings to the materials you are engraving, the conditions vary every time. It is essential to test your settings before proceeding with the actual engraving process. When performing tests, it’s best to use cheaper materials that you can usually find in Walmart to save money.

Practice safety when engraving

When you cut material away from the surface, it releases particles that can be harmful to your health. This includes nickel and chromium particles that are produced in the process. Always take precaution when using a laser engraver on stainless steel. Wear a protective mask and ensure the laser engraving machine is in a covered area to prevent people from inhaling harmful particles.

Laser engraving offers plenty of opportunities to transform stainless steel into works of art. When used correctly, you can get the optimum result that is clear, precise, and long-lasting. Keep in mind the best practices we listed above and start working on your first engraving project. And don’t forget to consider your safety in the process.